The Birth of a Diamond Ring

Making a diamond ring, or any jewel for that matter is a long-lasting art. Or science? Or both?

After all, one can't do it simply by planning and designing it. The metal, usually gold, needs to be melted and poured into a mold, then cooled once again. This process involves chemistry and extremely high temperatures. Also, as we know, the natural color of gold is yellow, so how did rose and white gold come to be? Once again, chemistry came to our aid and gave us methods to improve our art with the help of science and technology.

A lot of the work that was done manually in the previous century is now done with technological assistance. Many examples exist, some in the diamond planning, cutting, and polishing process. With the help of advanced cameras and innovative software, one looks at a rough diamond and calculates every possibility to what diamond can be extracted from the rough. An action that required 10 pairs of eyes and weeks of planning just 30 years ago, now is a matter of days with minimum room for errors.

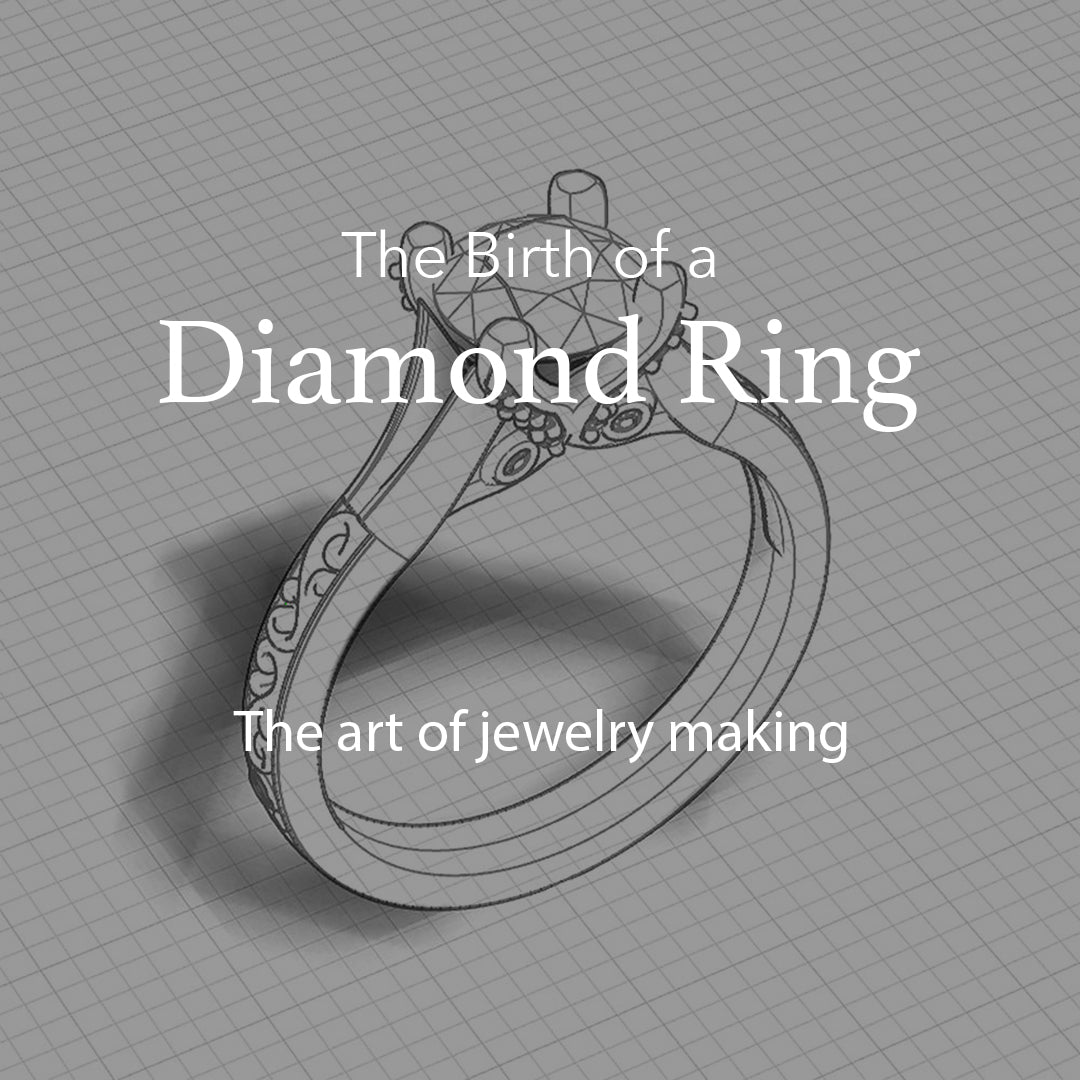

Designing

For the first step in the process of fine jewelry making which is of course the designing stage, some sophisticated software came to be, so a designer has their design along with all their editing possibilities rather than in their mind or drawn on paper.

Imagine that not so long ago, everything was planned and drawn manually. If something was off, the sheet was torn, and the designer had to do it all over again. But today, abilities and therefore capabilities are significantly enhanced. Countless software programs help us design a perfect jewel. We can also illustrate the jewelry in realistic colors and textures to see what it would look like in real life.

3D Printing & Gold Casting

The next stage is making a 3D model of the piece. In the old days, jewelers used to make this model by hand out of silver. Today we use 3D printers. So instead of one pair of hands working on one piece for several days, one printer can print many models in few hours. This is significantly cheaper, faster, and more accurate than the old techniques. Once the 3D model is complete, a silver model is being made.

In the next stage, the silver model is being used as the base for creating the main model. This model usually is made with gold. Platinum is also a common metal for diamond jewelry. It is far more resistant and brighter than white gold. On the other hand, a lot more expensive to process considering its chemical qualities. After casting the gold to the mold made with the silver model and cooling it down, we have a raw gold cast in the ring's shape. Now we can start making it a piece of fine jewelry.

Goldsmithing

After choosing the diamonds to be set in the ring, we start by preparing the ring for settings: making sure the proportions are right, adjusting the ring size, cleaning the setting areas to make sure it is shaped well for what is coming, getting rid of gold leftovers, polish and clean the ring and getting it ready for the diamonds. When it is ready, the diamonds are inlaid carefully in the ring. This is very delicate manual labor and it is done only by professionals. These people are trusted with tens of thousands of dollars and the customer's trust in the company. One small mistake can cost a fortune in the form of capital and reputation. At this point the ring is still rough, the gold is still rough and not bright at all. It is only after the setting of the diamonds in the jewel the ring will go on to its final stage.

Polishing

Polishing a diamond ring is like the unveiling of a painting. Slowly, this rough object is becoming an object of beauty. With every moment passes, the art is being shown and the atmosphere in the room begins to change. This is a moment in which everything must be perfect. One wrong move, and it's back to the silver model. We understand that sometimes, we hold faith in our hands. If this engagement ring won't be ready on time... Well, it should be. As far as we are concerned, there is zero room for error.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.